The Facts About Electrical Panel Phenolic Labels Uncovered

Table of ContentsThe Buzz on Electrical Panel Phenolic LabelsFacts About Electrical Panel Phenolic Labels UncoveredElectrical Panel Phenolic Labels Things To Know Before You BuyWhat Does Electrical Panel Phenolic Labels Do?7 Simple Techniques For Electrical Panel Phenolic Labels7 Simple Techniques For Electrical Panel Phenolic LabelsThe Best Strategy To Use For Electrical Panel Phenolic LabelsNot known Factual Statements About Electrical Panel Phenolic Labels

There are 4 collections of criteria made use of within the USA that directly deal with electrical panel labeling in some way. These laws are checked and connected by the Occupational Safety And Security and Health And Wellness Administration (OSHA), American National Specification Institute (ANSI), National Electrical Code (NEC), and the National Fire Protection Association (NFPA).

This is only a summary, and it is best to consult the laws in information to discover all the relevant information required for your center. The Occupational Safety And Security and Health and wellness Criteria govern every facet of workplace in the united state Within these regulations, a number of areas are directly appropriate to the security and informational labeling of electrical panels and devices:: "The phrasing of any sign ought to be easily reviewed and concise.

Some Known Details About Electrical Panel Phenolic Labels

While the scope of ISO policies covers a worldwide recognized requirement, the ANSI requirements have actually been adopted to define criteria within the U.S. There are thousands of ANSI requirements, yet the one essential for electrical panel labeling is ANSI Z535 and specifically ANSI Z535. 4 American National Requirement for Product Security Indicators and Tags.

- In cases where items have actually an extensive expected life or were exposed to extreme conditions, the product customer should call either the item maker or an additional resource to establish a means for obtaining replacement signs or labels". The NFPA oversees the development of the National Electric Code, and it was recently updated in 2020.

As we covered above, the guidelines set certain guidelines for the sizing, color, and information for your labels. Working within these limits, you should select appropriate requirements for your tag layout. Electrical panels been available in a range of shapes and sizes. It is very important to consider the surface and any kind of shapes that might exist in the desired location for labeling.

The Greatest Guide To Electrical Panel Phenolic Labels

They are suitable for a lot of electrical applications and have wonderful toughness and readability. Metal labels ought to be selected for applications needing durable sturdiness. Among the best materials offered is Metalphoto photosensitive anodized aluminum, which is used for labels and tags that require a rack life of over 20 years also in the toughest conditions.

Along with choosing electric panel tags, your facilities administration program need to also involve proper upkeep and inspection for your devices and your tags. With time labels, may end up being used or obsolete and require replacement to preserve the honesty of your electric system.

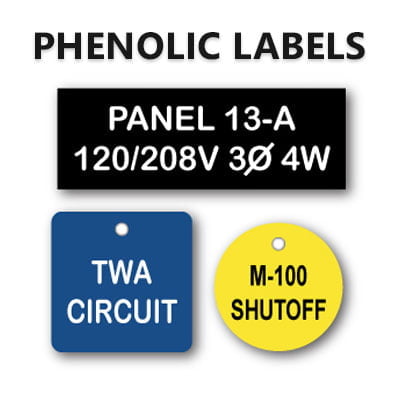

Phenolic tags are commonly utilized on electrical panels, shutoffs, incurable blocks, along with custom applications where phenolic materials are a requirement. Electrical Panel Phenolic Labels. Understood for its capability to stand up to greater temperature levels, along with its strength and stiffness, phenolic items are the perfect service for applications that need thermal resistance or resistance to particular chemicals

Unknown Facts About Electrical Panel Phenolic Labels

Equipment is often revealed to extreme conditions and safety determines that such locations have resilient labeling. These examples are cut out to accommodate control switches or levers and can be customized by dimension, shade and shape.

They are ideal for a lot of electrical applications and have terrific toughness and readability. Metal labels should be chosen for applications needing robust durability. Among the greatest products readily available is Metalphoto photosensitive anodized light weight aluminum, which is utilized for labels and tags that call for a life span of over two decades even in the toughest conditions.

Along with choosing electric panel labels, your centers management program must also include correct maintenance and evaluation for your tools and your labels. Gradually tags, may end up being used or outdated and require substitute to maintain the stability of your electric system.

The Ultimate Guide To Electrical Panel Phenolic Labels

Equipment is frequently revealed to harsh conditions and safety and security dictates that such areas have durable labeling. These examples are cut out to suit control buttons or levers and can be personalized by dimension, shade and form.

They appropriate for most electric applications and have fantastic longevity and readability. Metal labels need to be selected for applications requiring robust longevity. One of the strongest products readily available is Metalphoto photosensitive plated aluminum, which is used for labels and tags that need a rack life of over twenty years also in the toughest problems.

The 2-Minute Rule for Electrical Panel Phenolic Labels

In enhancement to picking electric panel tags, your facilities management program need to additionally include proper upkeep and assessment for your devices and your labels. Over this post time tags, may become used or out-of-date and call for substitute to preserve the integrity of your electric system.

Phenolic labels are commonly made use of on electrical panels, shutoffs, incurable blocks, in addition to custom applications where phenolic products are a demand (Electrical Panel Phenolic Labels). Recognized for its capability to endure greater temperatures, along with its stamina and stiffness, phenolic items are the ideal remedy for applications that need thermal resistance or resistance to specific chemicals

Machinery is often revealed to severe problems and safety determines that such areas have durable labeling. These instances are eliminated to suit control buttons or bars and can be personalized by size, shade and shape.

Some Known Questions About Electrical Panel Phenolic Labels.

They are suitable for many electric applications and have wonderful durability and readability., which is used for labels and tags that require a shelf life of over 20 years also in the toughest problems.

In addition to selecting electric panel tags - Electrical Panel Phenolic Labels, your facilities management program should additionally entail appropriate maintenance and inspection for your tools and your labels. In time tags, may become used or out-of-date and require substitute to preserve the stability of your electric system

Phenolic labels are commonly made use of on electric panels, valves, incurable blocks, in addition to custom applications where phenolic pop over to these guys products are a demand. Known for its capacity to stand up to higher temperature levels, in addition to its strength and tightness, phenolic products are the excellent service for applications that need thermal resistance or resistance to certain chemicals.

The Ultimate Guide To Electrical Panel Phenolic Labels

Machinery is usually exposed to extreme problems and security determines that such locations have resilient labeling. These examples are eliminated to suit control switches or levers and can be personalized by dimension, shade and shape.